Videos

Upgrading the F220 firmware

How to upgrade the masterboard and display firmware

Extender bus learn on F220 & F120A panels

How to perform an extender bus learn on the F220 and F120A panels

General Information Messages

This table provides descriptions for general information messages.

These messages are informative only and are shown in the current event queue along with defect events.

| Message | Description |

|---|---|

Walk Test ON

| The specified button has been pressed. All of these conditions are common across all LCD mimics; pressing the button on any mimic will toggle the state, even if activated from another LCD display. |

LED Mimic/WarnSys n Door

| The door is open on the specified mimic panel. This will generate a Door Interlock Defect if the main panel door is closed. |

Input Active | A loop device configured as input-only (no Bell or Brigade flags set) has activated. |

Fault Messages

This table provides descriptions for system defect messages.

These are defects detected on the F220 panel, other than those generated by loop devices.

| Message | Description |

|---|---|

| Loop nn open | An open-circuit condition exists on the specified loop. Note that this may in fact be due to a line short between loop isolator devices which have activated to cause the loop to open. |

| Loop nn short | A short-circuit condition exists on the specified loop. This will be generated where the short occurs between the loop driver and the first isolator device on the loop. |

| Loops x+y FAILED!(Timeout) | The specified loops are offline, as the loop driver controlling them has failed to respond to commands sent by the Mainboard. |

| Warn Sys Fault

Ext Bell Fault | The specified Bell relay circuit is open or short-circuit. |

| ACF Monitor Fault | The ACF relay is open or short-circuited. |

| Earth Leakage Fault (msg) | The Earth monitor circuit has detected a connection to Mains Earth

The value of msg is one of high, low or high +low |

| Program ROM CRC Check Failed | An error in the Program ROM area has been detected. This may indicate that panel operation will be unreliable. |

| Config ROM CRC Check Failed

| An error in the Configuration ROM has been detected. The second line indicates the affected area. This may indicate that panel operation will be unreliable, but limited to the affected data only. |

| NAND Fault | An error in one of the two copies of the boot flash memory has been detected. The panel will still boot on one good copy. |

| Memory Lock Switch Fault | The Configuration Memory Lock switch is OFF, outside the Engineers Menu. |

|

External Fault Active

| The EXT FLT input on the F220 Mainboard is open. |

| Door Interlock Fault | The F220 Mainboard door has been closed with certain panel functions active |

| LED Mimic/Amp n Timeout

LCD Mimic n Timeout | The LCD/LED mimic (or amplifier) has not responded to commands sent by the F220 Mainboard. |

| LED Mimic/Amp n Extra

LCD Mimic n Extra | There are more devices detected on the RS-485 mimic bus than are programmed into the configuration. |

| LED Mimic/Amp n Disp Fault | There is a defect in the LED mimic display board hardware. |

| LED Mimic/Amp n Interlock

LCD Mimic n Interlock | The interlock circuitry on the relevant mimic is off-normal. |

| LED Mimic/Amp n Ext Fault | The External Fault input on the mimic is active |

| LED Mimic/Amp n Fault | Some fault condition, other than the above, has occurred on the mimic. |

| Main LCD Timeout | The primary LCD display board is not responding. |

| FanCtrl xxx FAULT - StartFail | A Fan Control Block has not detected its associated fan running (Status) signal in time after triggering its Start output. |

| FanCtrl xxx FAULT - StopFail | A Fan Control Blocks associated fan running (Status) signal has remained active for too long after triggering its Stop output. |

| [COM PORT TIMEOUT]

RS-485 FAILURE !! | Shown on various LCD displays or LCD mimics when there is lost communications from the F220 Mainboard. These messages are generated on-board by the display hardware, as they are not receiving data from the panel. |

Loop Messages

This table provides descriptions for loop device event/messages.

| Message | Description |

|---|---|

| **ALARM** | Applies to a loop input device – detector, Manual Call-Point, or input module; when the device activates. The alarm may be one of the following:

Smoke either an intelligent smoke detector or a conventional smoke detector activation from a Loop Responder input. Call-Point either an MCP-type device or a Manual Call-Point activation from a Loop Responder circuit. Heat thermal detector. |

| Fault | Generally, Faults can be decoded to one of the causes listed below, however for some events this is not possible. |

| Pre-Alarm | Applies to detectors only. The analogue value being returned is approaching the Alarm level. |

| Duplicate Device | Two loop devices on the same loop have been assigned the same address. |

| Missing | A loop device that has been configured in the system memory is not present on the loop. |

| Extra Device | The loop driver board has detected one or more of:

Modules set to address 00 will not have their LEDs turned on. |

| Maintenance Alarm | The loop driver internal drift compensation has reached its threshold limit - the detector requires cleaning. |

| Type Mismatch | A loop device does not match with the configuration assigned to it in the system memory. |

| Self-Test Fail | A loop device has failed its regular auto test. |

| DIS | A loop device has been isolated through the DISABLE push-button on the front panel display or the User Menu. |

| Alarm Reset | A loop device that was in 'Alarm' has been 'Reset' through the RESET push-button on the front panel display. |

| Low Defect | Generated by sensing chamber defects in System Sensor detectors |

| High Defect | Generated by sensing chamber defects in System Sensor detectors - this can mean that the chamber is too dirty for the detectors internal drift compensation algorithm to operate. |

| Short Circuit | A monitored relay has a short-circuit. |

| Open Circuit | Generated by open-circuits on either monitored loop relays or modules. |

| Board Reset | A Pertronic Loop Responder has restarted. |

| Supply Defect | There is either a 'Defect' in the detector supply on a Loop Responder, or the external power supply on a Pertronic Loop Relay board is out of range. |

| Isolator Active | The on-board isolator relay on a Pertronic Loop Responder or Relay has activated due to a short-circuit on the loop. |

| AVF Stage 1 | A loop device with AVF enabled has been triggered once and is in the AVF delay period awaiting a second trigger. |

| Input Active | A loop device programmed with no output flags (i.e. one not generating an Alarm event) has activated. |

| Fan Relay Latched | A Pertronic Fan Relay unit has been latched active by its associated Fan Controller unit. |

| Circuit Resetting | A Pertronic Loop Responder circuit is in its self-timed reset phase after receiving a reset command from the panel. |

| Comms Error | Indicates that there is a loop device present at the location, but the data has been corrupted and cannot be interpreted. |

| Manual OFF | A SW3 device has been switched off. |

| Manual ON | A SW3 device has been switched on. |

Network Messages

This table provides descriptions for network messages.

These are messages reported to the F220 from a connected network and are logged by the F220. Each message will be prefixed by a network node number apart from the " SYSTEM OFFLINE" message.

| Message | Description |

|---|---|

| SYSTEM OFFLINE

Network Service Mode | The network the F220 is connected to has been put into Service Mode.

Network Service Mode is used for updating configurations for all nodes and all panels across the network from a single location. In network service mode, the network does not transfer normal operational information from panels so therefore no normal network functions are available. Each panel in the network will remain in service and operate independently, but the panels will not be able to send fire indications or fault indications over the network. F220 panels and mimics treat Network Service Mode as a System Event. Normal keyboard and display functions remain available (by pressing the keyboard buttons such as ok or menu). |

| Node X Node Config Mismatch Fault | The connected network card configuration does not match that stored by the other network cards.

This fault will be reported identically on all panels within the scope of the connected network card. The fault location will identify the network card (node) with the configuration mismatch. |

| Node X Panel Config Mismatch Fault | The panel configuration does not match that stored by the connected network card.

This fault will be reported identically on all panels within the scope of the connected network card. The fault location will identify the panel with the configuration mismatch. |

| Node X Timeout Fault | Network Card X is not responding |

| Node X Earth Fault | Network Card X has detected an earth fault condition. |

| Node X Net In TImeout Fault | Network Card X has reported the loss of network data at the IN connection |

| Node X Net Out TImeout Fault | Network Card X has reported the loss of network data at the OUT connection |

| Node X Panel Comms Errors | Network Card X has communications errors with its connected panel |

| Node X UBoot CRC Fault | Network Card X has detected a critical file which has been corrupted |

| Node X Aux Fault I/P Fault | Network Card X has an active Aux Fault input |

| Node X Timezone Mismatch Fault | There are differences between panels configured timezone settings |

| Node X Net Disabled Fault | Network Card X is connected to a panel which has not had networking enabled in its configuration |

System Events

This table provides descriptions for system event messages.

| Type | Description |

|---|---|

| Fire | Global Fire condition set. |

| Fault | Global Fault condition set. |

| Pre-Alarm | At least one detector is in pre-alarm state. |

| Common Disable | At least one device or zone is disabled. |

| Local MCP | MCP input on F220 Mainboard.

|

| Warn System On | WARN SYSTEM ON active.

|

| Ext Bell Disable

| (Not used) |

| Low Battery | Low voltage on battery or battery missing. |

| Mains Failure | Mains supply absent. Note that this is the actual state of the mains supply -it does not cause a Defect condition immediately. |

| Lamp Test | Activated when the F220 is in Global Lamp Test mode. Provided for lamp test of external equipment.

Local lamp test will not trigger this event. Note: LED outputs are overridden by Lamp Test and will therefore not operate, although they will be treated normally if used as a logical input. |

| Device Reset | Active for 40 seconds after system reset or power-up, or 5 seconds after a device (ZMU or BMIF types only) is reset via the 'System Panel' Intended for use with devices, which require a power-down to unlatch an 'Alarm' condition. |

| Alarm Acknowledge | (Not used) |

| Aux Defect | Active when the AUX DEF input on the main PCB is open-circuit. |

| Door Open | Active when any LCD Mimic or the main panel door is open. |

| Buzzer On | Active when the F220 buzzer is activated. |

| MCP Alarm | Active when any MCP device is in 'Alarm'. |

| Smoke Alarm | Active when any smoke detector is in 'Alarm'. |

| Thermal Alarm | Active when any heat detector is in 'Alarm'. |

| FanCtrl Latched | Active when any latched Fan Control Block, or Relay, with the ZoneTrip flag set, is active and therefore must be reset via the global FanReset output. |

| FanCtrl Reset | Active for at least 5 seconds (or when all FCB's have been processed) after the global FanReset output is activated. |

| FanCtrl Frozen | Active once the FCB Freeze Time period has expired |

| Deluge Ctrl Frozen | Active once the DCB Freeze Time period has expired |

| ACF Disable | AUX ISOLATE control is active. |

| DHR Disable | DOOR HOLDER ISOLATE control is active. |

| Night Mode | Active when panel is in Night mode |

| Warning System Isolate: Key-Switch | Active when a BCO key-switch input is active. |

| Warning System Isolate - Button

| Active when a pushbutton Silence Alarms input is active. |

| Global NBR Reset | Set for 5 seconds after the global Non-Brigade Reset function has been activated. |

| Brigade | Active whenever the main Brigade Fire relay is active.

|

| Delay | Active when a “Delay to Outputs” is operating (AS7240.2 section 7.11)

|

| Supervisory | Active when a supervisory signal is active |

| AVF Triggered | AVF is active |

| Relays Manually Activated | One or more relay outputs have been manually activated. |

| EWIS Trigger | When active (Alarm, PreAlarm, Fault, AVF) a detector or module can be

mapped to trigger an Emergency Warning and Intercom System (EWIS). Range 1 to 999 |

Power Supply Fault Indication Table

Possible causes of F220 power supply faults are

| Fault | LCD Message

(Keyboard-Display) | Comments | Controller Code (Local 7 segment display) | Fault Relay

De-energised | |

|---|---|---|---|---|---|

| Standalone Mode | Panel Mode | ||||

| Mains Lost | Mains Supply Fault | Occurs when input DC supply is less than 19.8 V. Clears when supply voltage is greater than 20.8 V and is stable for at least 1 second. | '1' | Y | N |

| Supply Low Voltage | Charger Low | Occurs when input DC supply falls below 25.2 V. Clears when supply voltage is 26.2 V or higher continuously for at least 1 second. | '2' | Y | N |

| Supply High Voltage | Charger High | Occurs when input DC supply is greater than 29.5 V. Clears when supply voltage falls below 28.5 V. | '3' | Y | N |

| Battery Missing | Battery Disconnected | Occurs when battery connected is less than 19 V or battery voltage falls below 19 V. Cleared when battery voltage is equal to 20V or higher.

Fault codes 'b' and '6' look similar.

| 'b' | Y | N |

| Battery Low | Battery Low | In normal operation, a battery low fault occurs when the mains supply is missing and battery voltage is between 20V and 22V. The fault is cleared when the battery voltage is 23 V or higher.

During autotest (in both panel and standalone modes), a battery low fault will be indicated when the voltage drops below a threshold range of 19V and 0.9 x float voltage. When the battery voltage goes below 0.9 x float voltage, the auto test will be aborted and the battery low fault will be latched. | 'L' | Y | N |

| Charger Fault | Charger Fault | In normal conditions, this fault occurs when charger voltage is below (0.9 x float voltage) or greater than 29.5V with mains supply present, where float voltage is based on current battery temperature.

Charger fault clears when charger voltage is greater than (0.9 x float voltage) + 1V (AS7240.4 - 5.4d). In boost charge mode, this fault is indicated only when the charger voltage is greater than 29.5volts. | '5' | Y | N |

| External Temperature Sensor Missing | Temp Sensor | Occurs when there is a read error from external/internal temperature sensor. It is not limited to only the external temp sensor. It can also occur when the external temperature is missing or not connected. Fault codes 'b' and '6' look similar.

| '6' | Y | N |

| DC Out Indication | Occurs when output DC voltage is below 24.4 V or higher than 29.0 V. This state will only be indicated on the PSU's 7-segment display. It is not a fault condition and will not activate the fault relay.

Clears when output DC voltage is in the range 24.7 V – 28.7 V Will not occur during automatic 'Battery Capacity' test. Will not occur if the mains is missing. | '7' | N | N | |

| Battery Charger Current High | Current High | On PSU H/W version 1.x Occurs when charger draws more than 4 Amps for 30 seconds. Clears when current drawn is below 4 Amps for 700 mSec. When the charger current increases more than 2 Amps for 5 seconds, the software reports a current high fault. On PSU H/W verions 2.x Except the threshold values across different product variants the logic to set/clear the fault remains the same. For 5A/11A variant: Charger high threshold is set to 3.5A For 22A variant, charger threshold is set to 6.5 A | '8' | Y | N |

| Charger Comms Lost | Comms Lost | Occurs when the communications between the panel and the charger board is lost for 10 seconds. | '9' | N/A | N |

| Charger Program CRC failure | Program CRC | Occurs when computed CRC value is not the same as the value stored in flash memory. | 'C' | Y | N |

| Load Shutdown | Output DC voltage is cut off when mains supply is missing and battery voltage falls below 13.5 V.

Clears when mains supply is turned on or battery voltage is .22V or greater. | 'F' | Y | N | |

| Auto Test | Not a fault. Just an indication on 7 segment display of charger controller. Occurs when charger controller goes for auto-test. This test is run for 40mins.

The test will automatically abort if

| 'A' | N/A | N/A | |

| Watchdog Reset | Occurs when the most recent reset of Charger Controller was due to watchdog failure | 'd' | Y | N | |

| Trickle Charge | On PSU H/W version 2.x Only indicated on 7-segment display and not present on 485 data output. PSU enters trickle charge mode when system current exceeds the thresholds list in Table 14‑4 ).The PSU switches back into normal charging mode when system current falls below the thresholds listed in Table 14‑4. | 't' | N/A | N/A | |

- The decimal point of the 7-segment display will toggle every half second (500ms On, 500ms Off) in Normal Charge mode and be on, steadily, when the charger is in ‘Boost Charge’ mode.

- In Panel Controlled mode, the fault relay will operate (de-energise) only in the case of complete PSU failure.

- In Standalone Mode, the fault relay will de-energise for all PSU fault except ‘DC Out’.

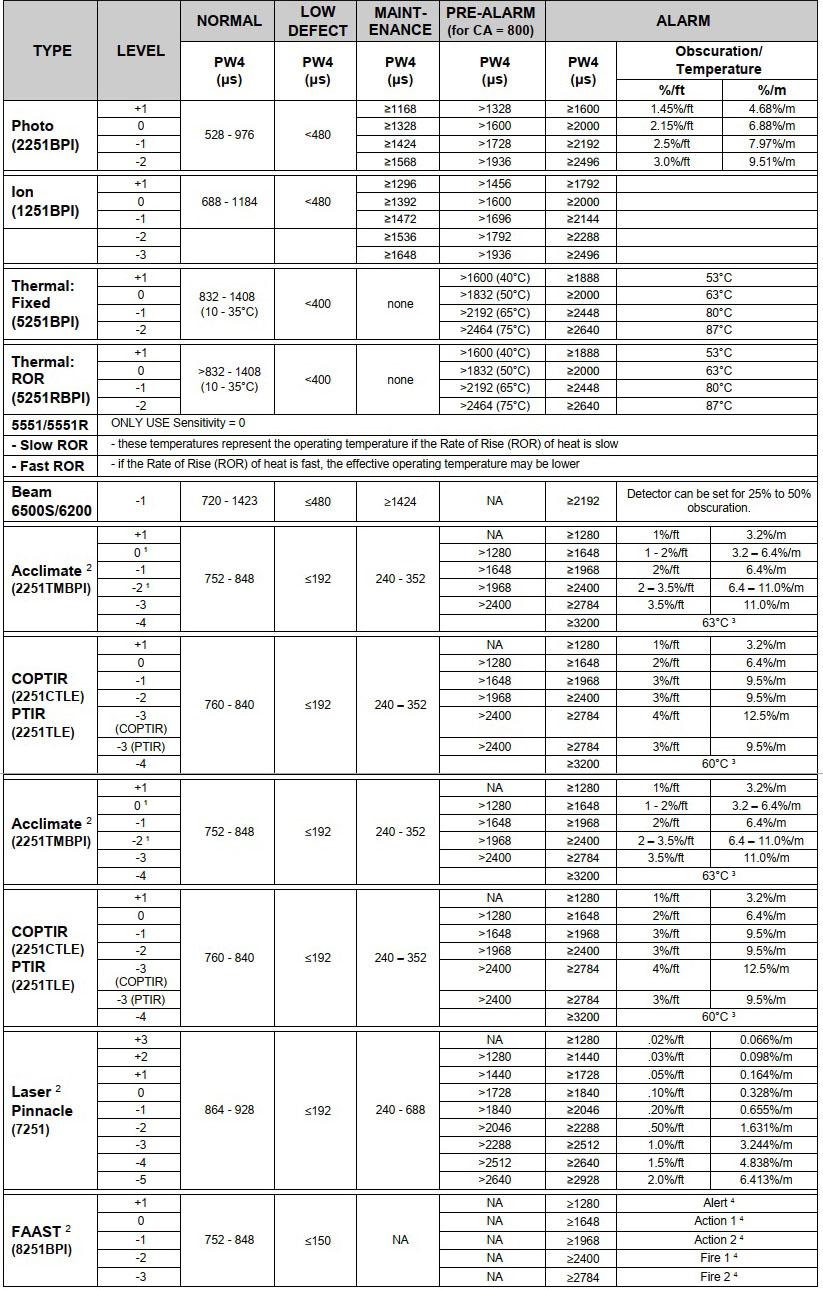

Detector Sensitivity Table

Provides a guide to the detector sensitivity configured and the actual level required to generate an alarm.

Notes

The actual sensitivity of the Acclimate detector at levels 0 and -2 is determined by the internal algorithms of the detector itself. In “noisy” environments the actual sensitivity decreases towards the lower sensitivity in the range (higher %/m value), and in “quiet” environments the higher sensitivity (lower %/m) is used.

For the intelligent detectors (Acclimate, Pinnacle & FAAST), the detector outputs a set of fixed, discrete levels for each sensitivity setting. Pre-alarm condition is determined by looking for an active level at the next-highest setting There is no Pre-Alarm warning available on the highest sensitivity level, therefore it is recommended that detectors are not ‘Brigade Calling’ at the highest sensitivity level.

At the lowest sensitivity (-4), the Acclimate, COPTIR and PTIR are Heat only detectors.

See FAAST sensitivity table below

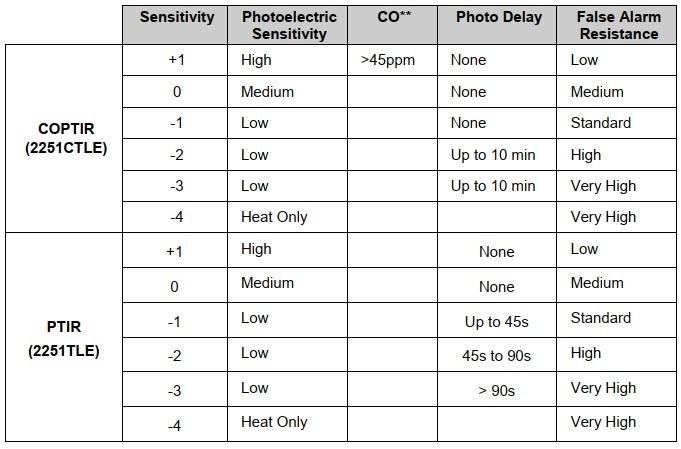

COPTIR/PTIR Sensitivity Table

The table below summarises the principal properties of the COPTIR and PTIR at the 6 available sensitivity settings.

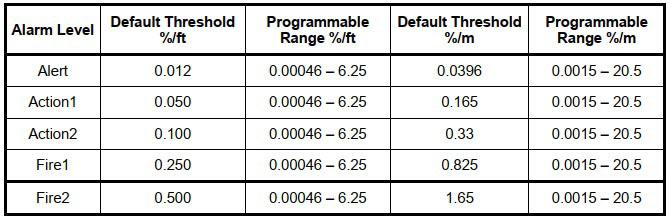

FAAST Sensitivities Table

The FAAST has 5 named alarm threshold values that are locally assigned to the device via the PipeIQ configuration software as follows:

Mimic Buses

External High-Speed RS-485 Bus

The F220 External High-Speed RS-485 Bus runs at 115.2 kb/s. It is used to connect the remote F220 Keyboard Display (Mimics) such as the F220-FFMN, F220-EMMN and F220-AMMN, as well as the 485LAC Mimic Driver, 12-way LED Smart Card, EA60/EA120 amplifiers, and future peripheral units.

The maximum number of LCD Mimics that can be attached to the External High-Speed RS-485 bus is 32 and, for the LED Mimics, 8, and amplifiers, 16. In combination, the total number of LCD, LED mimics, and amplifiers cannot exceed 32.

| Device | Mainboard Connector | Mainboard Label |

|---|---|---|

| Remote F220 Keyboard-Displays

(Full function master mimic) | K29

K26 | EXT HIGH SPD RS485

HIGH SPD RS485 |

External High-Speed RS-485 Bus Connectors

Note:

- It is essential that external devices connected to the External High-Speed RS-485 Bus are wired in daisy-chain fashion using twisted pair cable and that a 120 Ohm bus terminating resistor is connected across the last device.

- Spur wiring is not permitted.

Internal High-Speed RS-485 Bus

This bus carries communication between the Mainboard, Keyboard-Display, Net2Card, Charger Controller, and EA60/EA120 Amplifiers

| Device | Mainboard Connector | Mainboard Label |

|---|---|---|

| Charger Controller | K39 | CHARGER CONTROLLER |

| Unassigned | K39, K41, K43, K44, K45 | HIGH SPD RS485

|

| Keyboard-Display | K42 | F220 KEYBOARD |

| NET2CARD | K39, K41, K43, K44, K45 | HIGH SPD RS485

|

| NET2GATE | K39, K41, K43, K44, K45 | HIGH SPD RS485

|

| EA60/EA120 Amplifiers | K39, K41, K43, K44, K45 | HIGH SPD RS485

|

Internal High-Speed RS-485 Devices and Connections

Low Speed RS-485 Bus

This bus is used for connecting a range of existing Pertronic products that operate at 9600 b/s. Up to 32 devices can be connected to the Low Speed RS-485 Bus.

The following devices may be connected to the Low Speed RS-485 Bus

| RS-485 Device | Master | Polled Slave | Slave |

|---|---|---|---|

| LED Mimic: 12-Way Smart LED board | Yes (1 – 8) | No | No |

| EVAC50W24V Amplifier (set as LED–1-8 Amplifiers) | Yes (1 – 8) | No | No |

| EA60/EA120 Amplifier (set as LED 1-8 Amplifiers) | Yes (1 – 8) | No | No |

| EVAC50W24V Amplifier (set as LCD–9-16 Amplifiers) | Yes (1 – 8) | No | No |

| EA60/EA120 Amplifier (set as LCD 1-8 Amplifiers) | Yes (1 – 8) | No | No |

| LED AFI (LEDAFIC) | Yes (1 - 8) | No | No |

| LED Address Controller: | Yes (1 – 8) | No | No |

| RS-485 Ancillary Peripherals: connect to 12-Way Smart LED board or LED Address Controller | |||

| 8-Way LED Extender board (F100PDB) | |||

| 8-Way AFI Display (AFI-8WAY) | |||

| 8-Way LED Relay board (F100ZDRLY) | |||

| LED Zone Address Offset board (LAC12W) | |||

| 48-Way Open-Collector board (48WOC-IF) | |||

| 24-Way Open-Collector board (24WOC-IF) | |||

Low Speed RS-485 Devices

The maximum number of LCD Mimics that can be attached to the Low Speed RS-485 bus is 32 and, for the LED Mimics, 8. In combination, the total number of LCD and LED mimics cannot exceed 32.